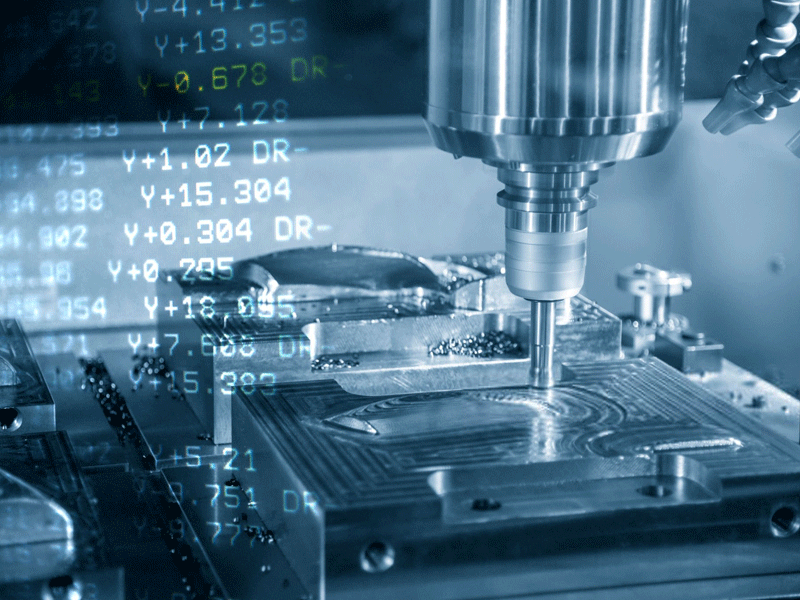

CNC milling is a computer-controlled subtractive manufacturing process that uses rotating cutting tools to precisely remove material from a workpiece, shaping it into a custom-designed part. Known for exceptional accuracy, this method can achieve tolerances as tight as ±0.02 mm, making it ideal for producing complex geometries across industries like aerospace, automotive, and medical device manufacturing.

How Does CNC Milling Work?

The CNC milling process involves four key stages:

1.CAD Design

Engineers create a detailed 3D model of the part using CAD software (Computer-Aided Design), specifying exact dimensions, geometries, and tolerance requirements.

2.CAM Programming

The CAD file is imported into CAM software (Computer-Aided Manufacturing), which translates the design into machine-readable G-code. This code dictates toolpaths, spindle speeds, feed rates, and cutting sequences.

3.Machine Setup

The workpiece is securely clamped to the CNC mill's worktable. Operators load tools (end mills, drills, etc.) and input the G-code to prepare for automated operation.

4.Automated Machining

The CNC machine executes the programmed instructions, precisely removing material through rotational cutting motions and multi-axis movements to produce the final part.

Key Advantages of CNC Milling

1.Unmatched Precision

Computer-controlled automation eliminates human error, ensuring consistent adherence to tight tolerances—even for intricate designs.

2.High Efficiency

CNC mills operate 24/7 with minimal supervision, significantly outperforming manual machining. Rapid tool changes and optimized toolpaths reduce production time, making the process cost-effective for both prototypes and large batches.

3.Design Flexibility

Capable of producing everything from simple brackets to complex contoured surfaces, CNC milling accommodates design iterations without requiring new tooling—a critical advantage over casting or injection molding.

4.Material Versatility

Compatible with metals (aluminum, steel, titanium), plastics (ABS, PEEK), and composites, CNC milling adapts to diverse industry needs while maintaining precision across materials.

5.Repeatability

Identical parts can be reproduced flawlessly over multiple production cycles, ensuring quality consistency for critical applications.

Cross industry applications

From automotive components to aerospace, CNC milling bridges the gap between digital design and functional hardware. Its ability to combine precision, speed, and material adaptability makes it the cornerstone of modern manufacturing.

What Is CNC Turning?

CNC turning is a precision machining process designed for creating cylindrical components. In this method, a stationary cutting tool removes material from a rotating workpiece, producing parts like shafts, bushings, pins, and threaded rods. Widely used in industries such as automotive, aerospace, and energy, CNC turning excels at manufacturing rotationally symmetric parts with tight tolerances (typically ±0.005 mm) and smooth surface finishes.

How CNC Turning Works

1.Workpiece Setup

The raw material (metal, plastic, or composite) is secured in a motorized chuck, which rotates the workpiece at high speeds (up to 4,000 RPM or more, depending on material).

2.Toolpath Programming

Machinists use CAM software to convert CAD designs into G-code, dictating tool movement, spindle speed, and feed rates.

3.Material Removal

As the workpiece spins, computer-controlled cutting tools (e.g., carbide inserts) move linearly along the X and Z axes, shaving away excess material to achieve the desired diameter and shape.

4.Finishing

Optional secondary operations like grooving, threading, or knurling can be integrated into the same setup for complex geometries.

Key Advantages of CNC Turning

1.Rapid Production for High Volumes

The continuous rotational motion enables faster material removal than milling, making it ideal for bulk manufacturing of cylindrical parts.

2.Reduced Operational Complexity

Simplified toolpaths and minimal axis movements shorten setup times, allowing quicker transitions between jobs.

3.Material Efficiency

Precise chip control and optimized stock usage minimize waste—critical for expensive materials like titanium or PEEK thermoplastics.

4.Superior Surface Quality

High-speed machining paired with fine finishing tools can achieve surface roughness values as low as Ra 0.8 μm, often eliminating post-processing.

5.Cost-Effective Repetition

Once programmed, CNC lathes produce identical parts with near-zero variance, reducing per-unit costs for large batches.

Applications in Industry

Automotive: Engine pistons, drive shafts, and valve stems

Medical: Implant connectors, surgical tool handles

Aerospace: Hydraulic fittings, landing gear bushings

Electronics: Heat sink cores, sensor housings

Why Choose CNC Turning Over Milling?

While CNC milling dominates complex 3D shapes, turning is unmatched for:

✅ Radial symmetry (e.g., tapered rollers)

✅ Faster cycle times for round parts

✅ Lower tooling costs for high-volume cylindrical components

Hot News

Hot News