Discover the key differences, applications, and decision-making strategies for optimal results.

Understanding the Core Technologies

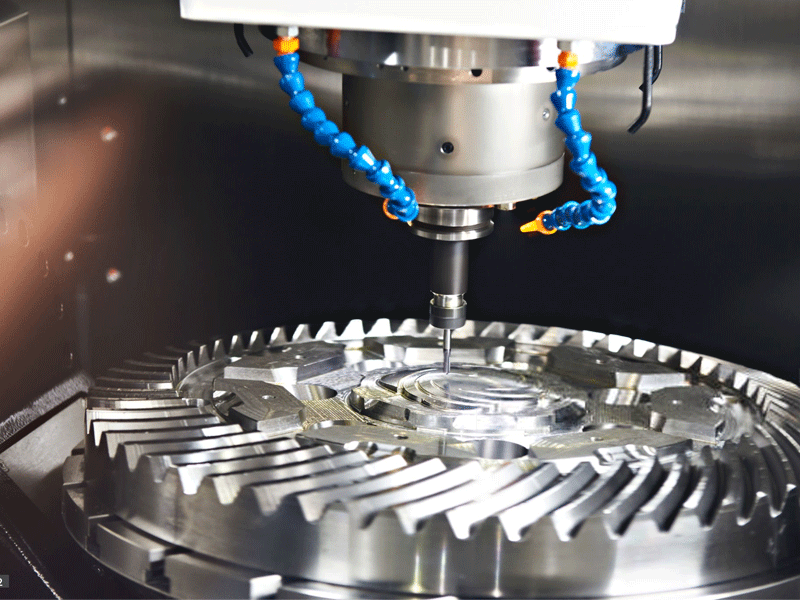

CNC Milling and CNC Turning are both computer-controlled subtractive manufacturing processes, but they excel in fundamentally different applications:

| Process | Primary Function | Best For |

| CNC Milling | Uses rotating multi-point tools to carve material from a stationary workpiece. | Complex 3D geometries, slots, pockets, and intricate contours. |

| CNC Turning | Rotates the workpiece while a single-point tool removes material linearly. | Cylindrical/symmetrical parts like shafts, bushings, and threaded components. |

Key Differences at a Glance

1. Motion Dynamics

Milling: Tools move along 3–5 axes (X, Y, Z + rotational) for multi-directional cuts.

Turning: Workpiece spins on a lathe while tools move linearly (typically Z-axis).

2. Geometric Capabilities

Milling: Creates complex shapes (e.g., aerospace brackets, mold cavities).

Turning: Optimized for radial symmetry (e.g., engine pistons, hydraulic fittings).

3. Efficiency & Cost

Milling: Higher setup complexity but unmatched design flexibility. Ideal for prototypes and low-to-medium batches.

Turning: Faster cycle times and lower per-unit costs for high-volume cylindrical parts.

| Factor | Choose CNC Milling | Choose CNC Turning |

| Part Geometry | 3D contours, pockets, undercuts | Cylinders, cones, discs, threads |

| Production Volume | Prototypes, small batches (<1,000 units) | High-volume runs (>5,000 units) |

| Material | Metals, plastics, composites (e.g., titanium, PEEK) | Bar stock, tubes, cast blanks (aluminum, brass, steel) |

| Tolerances | ±0.02 mm for multi-axis precision | ±0.005 mm for radial consistency |

| Lead Time | Longer setup, ideal for custom toolpaths | Rapid setups, repeatable automation |

5 Pro Tips for Optimal Process Selection

1.Start with CAD: Use 3D models to assess geometric complexity.

Milling: Required for >3-axis features.

Turning: Sufficient for axisymmetric designs.

2.Evaluate Material Waste:

Turning minimizes scrap for cylindrical stock.

Milling excels with block-like raw materials.

3.Prioritize Surface Finish:

Turning achieves Ra 0.4–1.6 μm without post-processing.

Milling may require grinding/polishing for mirror finishes.

4.Budget for Tooling:

Milling: Higher tooling costs (multi-axis setups).

Turning: Cost-effective for standardized tooling.

5. Hybrid Solutions: Combine both for parts like flanged shafts – mill features onto turned bases.

Why Partner with KETUO Machine for Your CNC Needs?

As a certified ISO 9001:2015 machining specialist with 15+ years of expertise, CFS Machine delivers:

✅ End-to-End Solutions: From CAD/CAM design to post-processing.

✅ Industry-Leading Precision: ±0.005 mm tolerances across 3/4/5-axis milling and Swiss-style turning.

✅ Material Mastery: Machining 50+ metals, plastics, and composites.

✅ Scalability: Prototype to full production runs (1–100,000+ units).

Hot News

Hot News