CNC automation is revolutionizing what we make in factories. It controls machines that make parts and products with computers. That means the TOHUAS cnc machining can work more quickly, make fewer errors and do not grow tired as people do. TOHUAS is a firm that specializes in creating these intelligent machines. They assist other companies in making things more efficiently and of higher quality.

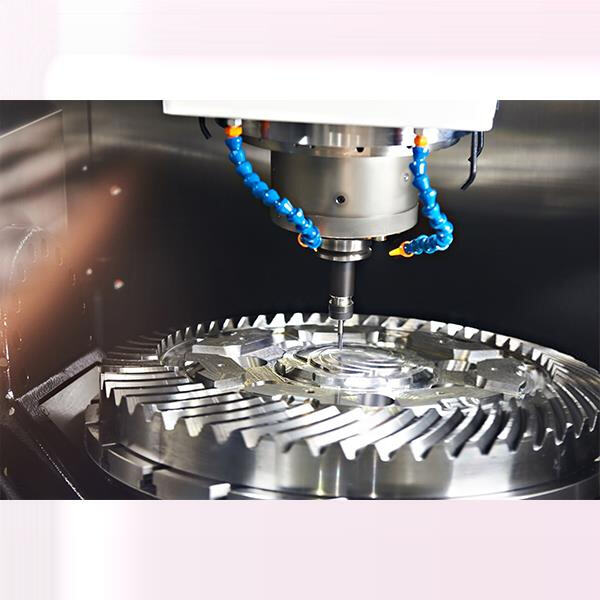

TOHUAS provides precision CNC automation to ensure production is smooth & efficient. These TOHUAS cnc machining are quite precise, so every part they produce fits exactly and there are no waste products. That's less time manually fixing mistakes and more time making money from more things. Factories can also make goods far more quickly, and with less waste, which saves both money and natural resources.

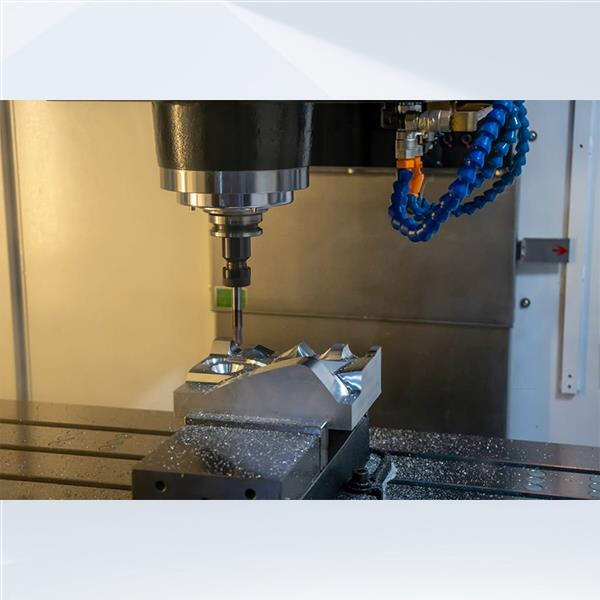

In fields where machines run 24 hours a day, 7 days a week, reliability and longevity are crucial. TOHUAS produces CNC machines that are rough and ready to put in some hard hours without falling apart. This TOHUAS cnc machining is making it easier for factories to keep running without frequently stopping to repair machines, which can be expensive and slow production.

The whole process of TOHUAS is run by advanced CNC production equipment. From task initiation to task completion, computers organize and control every step. That means the TOHUAS steel machining parts can work alone much of the time and people can tend to other important tasks. It operates the entire factory in better harmony.

Factories gain the ability to produce more products in less time with TOHUAS' CNC systems. It’s because the TOHUAS steel machining parts can be faster and less error-prone. And because the machines do much of the work, factories don’t have to keep as many people working at any one time which means we don’t have to pay as many wages to the workers. Cheaper and more products get produced, so factories make more money.