When you’re making something that goes into a machine or building, precision is important. That’s where Precision Casting Parts enter the picture, produced by firms like TOHUAS. They’re crafted in a very special way, to ensure that they are perfect for the job they need to do. TOHUAS embraces cutting edge technology and techniques to produce parts that literally fit perfectly and perform exceptionally.

When it comes to automated machinery processes, you demand that the equipment is built to the highest quality standards and that they run smoothly without interruption. These parts adhere to the particular machine specifications, resulting in machines operating at peak performance. In cars, in planes, in factory equipment wherever there’s a mechanism that’s got to operate just so, it’s TOHUAS Stainless Steel Casting parts that are making certain that it does. Like having the one piece of a puzzle that, once fitted in place, reveals the whole picture without any gaps.

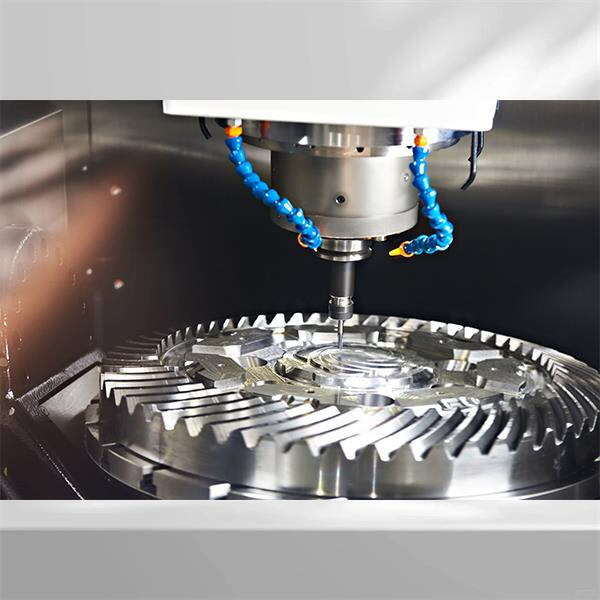

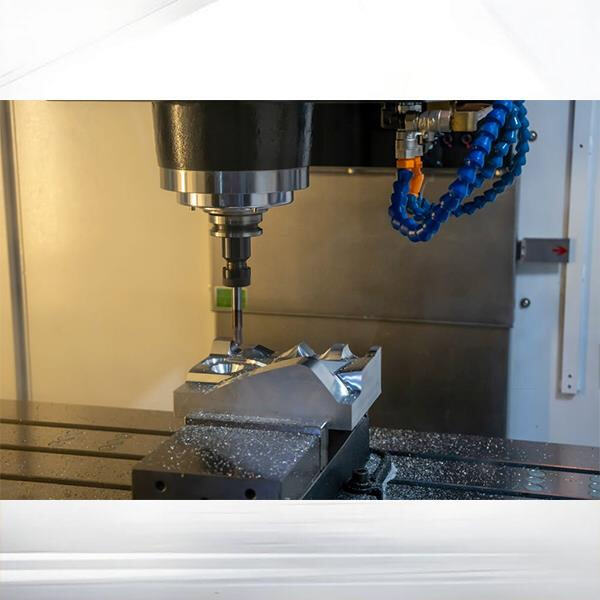

TOHUAS employs state-of-the art technology when manufacturing its cast parts. That means they can build parts that are not just strong but also incredibly intricate. The CNC Machining work with computers and special machines to pour metal into molds that are just the right shape. This process helps produce parts that are exactly the same each time and that's a big deal when you need to make things like engines or airplane parts that need to be super reliable.

Aftermarket parts from TOHUAS are not only exact, they're built to last. They are made from resilient materials that can withstand heat and pressure, yet not get broken. It’s perfect for things that get used a lot and need to be tough, such as parts inside a car engine or machines in a factory. With TOHUAS parts, you can be confidently assured that you get exactly what you paid for and they will keep doing so for a long time, saving you money and time down the road.

Precision engineering is TOHUAS’s stock in trade. This is because they design and make their own components so carefully that they fit perfectly together. Their engineers apply the magic of math and science to determine the best way to fabricate each part. This careful design work can help machines be more efficient, saving energy and making them faster. It’s akin to taking the quickest route home from school — you save effort and time.