It can be difficult to decide the best way to produce complex parts from sheet metal. Here at TOHUAS we are aware that they all don’t look alike, so knowing the suitable alternative will help you make a decision. The two of the most popular processes include laser cutting and stamping, along with bending. All of those different sheet metal machining methods have their own benefits and are good for different types of work. By seeing the ins and outs of these processes, one can determine which is best for your use-case.

Custom Sheet Metal Processing Process Selection: Laser Cutting vs. Stamping and Bending for Complex Parts

If it’s essential to choose the correct custom sheet metal fabrication technology for complex parts, there are a few more considerations that will help you get the best results. First, let us look at the part’s design. If your part is filled with a lot of fancy shapes or holes, however, you probably are best to go wirh laser cutting. This technique involves the use of a laser to cut and is fine for intricate designs. On the flip side, if you have to turn out lots of duplicates fast, stamping might be the way to go. Stamping deploys a die to literally stamp the outlay into the metal, and it’s fast. Also consider the thickness of the metal. CNC Machining like Laser cutting can accommodate a range of thicknesses, while for thinner sheets, stamping is often preferred. Another factor is the cost. Laser cutting can be more expensive to set up but in the long run, if you have complex designs, it is worth it. Another operation to be considered is bending. If your part requires a specific shape, bending can also provide many angles and curves without difficulty. It’s also used in combination with cutting techniques to form the final product. And keep in mind that the best decision for you will vary depending on your individual requirements, budget and design complexity.

It's important to know the distinction between laser cutting and punching when it comes to sheet metal fabrication. Let’s start with laser cutting. This is a highly reliable method that generates even complex shapes using relatively little waste. A compressed laser beam cuts through metal, meaning that it can process highly detailed designs that might be too intricate for other techniques. You can also easily swap designs, good for custom jobs. If, for instance, you want to adjust a size or shape, it is generally quick and easy. But laser cutting might be slower than stamping for a production run or in significant quantity.

Now, let’s talk about stamping. This technique is great for creating a lot of parts fast. A punch can stamp the metal into a form, and so it is ideal for mass production. Simple shapes can also be die-stamped at lower cost per part. But it may not be equipped to manage highly intricate designs as efficiently as laser cutting. It’s good for flat parts or parts that don’t require fine detail. The decision between these is how much of the speed / precision trade off you are, for your project, prepared to go. At TOHUAS, we explain these differences to assist in your decision of which type would be best for you and your sheet metal requirements.

Typical Problems Faced in the Use of Laser Cutting, Stamping And Bending Processes For Sheet Metal

In sheet-metal fabrication, companies like TOHUAS might use different procedures in making its parts. The three primary processes are laser cutting, stamping and bending. Both methods have challenges that can arise during manufacturing. It can also take a long time to cut thick metals using lasers. This has to give students the sense that you can look at a problem, think about it, and build something in a couple days. By contrast, laser cutting is slow: Using 22 tiles of Plexiglas as practice material prompting some students to cut out rectangles overnight in order to keep up with the pace I found that one takes anywhere from two minutes and eleven seconds each on the low setting (which didn’t cut all the way through), to three minutes apiece on high power which worked but produced smoky edges. That means if your project involves many parts, needed quickly as most engineering projects do — then this might not be a good bet. And the heat of the laser can alter, or warp, the shape of metal. This can cause the Steel Machining Parts not to fit together well, a big problem if you need to assemble them later.

Stamping is a different technique and has its own problems. One problem is that the dies used for stamping can deteriorate over time. That’s because if those dies aren’t swapped out frequently, the quality of one component in the parts will decline. And, the stamping isn't necessarily ideal for very complex shapes. Stamping can be difficult if there are a lot of curves or details in the design of the part. Finally bending is a problematic task. If you bend the metal too far, it can break. This especially applies to thin metal or metal that has been shaped/cut in some way. Understanding these issues is important for the workers at TOHUAS who are choosing the best method for their particular project.

A Comprehensive Overview

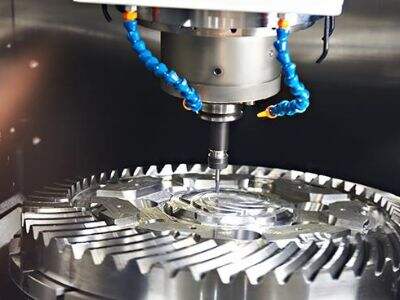

Sheet metal processing refers to the cutting and forming of sheet metal parts. TOHUAS plastic-slab technique is used by companies like TOHUAS to manufacture everything from car components to kitchen appliances. To understand sheet metal processing, the first thing that needs to be done is to learn the various methods. Laser cutting employs a highly concentrated beam of light to cut metal. I mean it’s very, very precise, and you can do close designs. But it might not be fast enough for thicker stuff.

Stamping, in contrast, involves the use of heavy machinery to force metal into a form. This is typically faster than laser cutting, and is ideal for rapid production of countless identical parts. And bending requires tools to bend the metal in and out. It is commonly employed to make parts of an assembly that have to fit into another part in a certain position. All these techniques have their own advantages and limitations. Companies like TOHUAS need to know these so they can select an option that fits their needs. By understanding how each method works, they can produce the high-quality parts their customers demand.

Laser vs Stamping and Bending

For a variety of complex parts made from sheet metal, TOHUAS is often forced to choose among laser cutting, stamping and bending. Both have their strengths. Best for intricacy Laser cutting is ideal when you want detailed designs. It’s capable of producing complex shapes that other techniques may find challenging. If a component includes many teeny holes or elaborate patterns, laser cutting is often the way to go. But it can be slower and more expensive, particularly for thicker materials.

Stamping is a fantastic way to produce large volumes of repetitive parts quickly. It is good for simpler shapes and can create many pieces in a short time. But if the design is too intricate, stamping may not be the best solution. Bending is especially necessary when the piece must be fitted to specific angles. It is typically used in combination with other techniques. For instance, a part could be stamped and the bent into proper form. Ultimately, whether to laser cut, stamp or bend depends on part design, how many are required and your budget for the project. By taking these into consideration, TOHUAS can determine the most suitable approach for a given job and consistently deliver high-quality results.